Three-dimensional Arowal wallboards produced at 50x50 (Cm) sizes have 3 layers of velvet lacquer, pvc coating and plain color (raw polymer). These three-dimensional wall panels, which are very popular in modern design and lacquer design, are very easy to install. With the experience and skill of the team, the installation team of Arrow is ready to install and install this 3D wall cover all over the country. The following is a brief description of the installation and implementation of these three-dimensional decorative panels:

To get the desired result, you have to prepare the level of work, but the benefits of three-dimensional walling can be pointed out on any surface, so there is no special preparation for installation. Only in the walls of the wallpaper are the paper cut off. And then we install the 3D panels. Of course, in cases where the wall is not yet working, or the surface under brick, block, cement or concrete, it should smooth the work surface fairly. Of course, the feature of this product is that it does not necessarily need to be perfectly smooth, but it can be aligned with the following adhesive.

For installation of 3D panels, a tile adhesive is used which can be easily applied at any level and adapted well to the environment, and depending on any type of work, we specify the concentration of the adhesive. Another can be used like an aquarium, cement glue or gypsum.

After preparing the glue for the best possible installation of the decorative panels in the four areas of adhesive, and then tie these three-dimensional wall panels to the desired level.

Since the designs on the three-dimensional panels are tiled, we can easily put them together on the wall, we just have to be careful that the walls are continuous and complementary, so that they are beautifully unique in the interior decoration of the house. do.

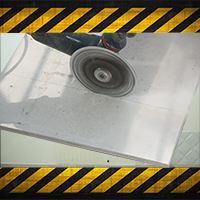

In simple color-coded panels, if there is a need for a special cut and work on a surface, these panels can easily be cut and desirable, but they can not be cut in lacquer-velvets and Pvc coatings. Be

In simple colored polymer panels, it is possible that, if requested by the customer, the spacing between the walls is sealed with concrete and work seamlessly seen and the seam between the panels is not seen, but in modern design and design specific architects to this side It was found that the distance between the Tiles is clear and there is no need to restrain it. The possibility of plucking in velvet lacquer and PVC coatings is not possible.

Polyvinyl polypropylene can easily be painted and any color (except powder and static color) can be painted.

Arawall Decor Co. after extensive research started its activity in the field of building materials in 1392 with the purpose of producing new and up-to-date materials. One of the products of this company is three dimensional polymer parts which has come to mass production under the name of “Arawall” since the beginning of 1395, after two years of advanced and specialized research.